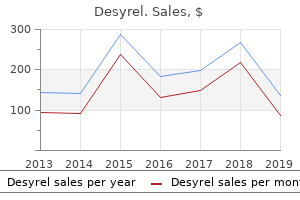

Desyrel

"Buy cheapest desyrel and desyrel, anxiety dogs".

By: P. Benito, M.S., Ph.D.

Co-Director, Oklahoma State University Center for Health Sciences College of Osteopathic Medicine

Careful evaluation of physiologic age anxiety symptoms hives order cheap desyrel line, medical comorbidities anxiety symptoms vision problems discount desyrel online master card, and functional status will help determine whether a patient may be eligible for transplantation anxiety reduction techniques cheap desyrel 100mg mastercard. A thorough physical examination may identify abnormalities that affect transplant suitability anxiety 7dpo generic 100mg desyrel amex, such as poor dentition or diminished arterial pulses. Each coexisting illness should be evaluated for its potential effect on transplant outcome. In addition, total disease burden and functional capacity must be factored into a final decision. Both the American Society of Transplantation (2001) and the Canadian Society of Transplantation (2005) have published clinical practice guidelines for the eligibility of kidney transplant recipients. Because little evidence is available to guide the evaluation process, most recommendations are based on expert opinion. Patients who receive a preemptive kidney transplant have a superior outcome as compared with patients who undergo dialysis treatments before receiving a transplant. Similarly, length of exposure to dialysis affects transplant outcomes and mortality. Determining suitability for transplantation may require multiple specialist visits and medical tests. At present, patients over 65 years of age are the fastest-growing group of wait-listed potential recipients. With advanced age, special attention should be paid to pretransplant medical comorbidities, functional status, and quality of life. The cost of maintaining a proposed recipient on the waiting list is not insignificant. The technical aspects of the transplant surgery limit transplantation in extremely young children. However, this should not delay transplant workup, and preemptive transplantation should be considered when possible. Recent analyses suggest that allograft failure secondary to recurrent disease is now the third-most common reason for graft failure, only behind rejection and death with a functioning graft. Similarly, when the Mayo Clinic retrospectively analyzed specific causes of kidney allograft loss, recurrent disease was diagnosed in 14. Despite this, the risk for recurrence rarely precludes transplantation, and allograft failure from recurrence is rare in first 5 years posttransplant. It is important to counsel prospective transplant recipients about the risk for recurrent disease. IgA nephropathy may recur in up to 60% of allograft biopsies; however, clinically significant recurrence (with elevated creatinine or proteinuria) develops in only 30% of kidney transplants. Additionally, long-term graft failure rates and mortality are higher among obese recipients when compared with otherwise comparable recipients. In many cases, recurrence appears to be secondary to a circulating permeability factor that affects podocyte foot process and glomerular slit diaphragm integrity. Unlike in the nontransplanted kidney, spontaneous remission is rare and graft failure can occur in as many as 50% of cases by 10 years. Recurrence of rapidly progressive glomerulonephritis is rare if disease is quiescent at the time of transplantation. Recurrence of lupus nephritis is rare (<20%), possibly because of protection from immunosuppressive transplant medications. Glomerular diseases with organizing deposits such as amyloidosis, fibrillary, and immunotactoid glomerulonephritis can all recur with rates greater than 50%. With both primary and secondary forms of amyloidosis, transplantation is often limited by severe cardiac disease; early death from cardiovascular disease or infection is quite high. Patients with primary oxalosis are highly susceptible to rapid oxalate deposition in the transplanted kidney without treatment. These patients are best managed with concurrent liver transplantation and supplementation with orthophosphate and pyridoxine.

This endotherm is a result of the ionic liquid present within the fibers and its decomposition anxiety symptoms upon waking up buy discount desyrel 100mg on-line. The washed fibers generally have a lower heat released (H) anxiety symptoms 37 desyrel 100mg on-line, which implies that the stabilization time required for the oxidation of the fibers can be reduced [7 anxiety symptoms for 3 months buy genuine desyrel on-line, 8] anxiety disorder 100 symptoms purchase desyrel 100mg. The increase in the carbon yield is a direct result of the polymer chains having a higher content of oriented crystalline regions forming stronger ladder structures during stabilization. The fibers exhibited uniform cross sections, free from micro-voids, with smooth surface morphologies. Cost drivers in the ionic liquid synthesis will be identified through a techno-economic analysis of ionic liquid production. Dai: 2020 Max Bredig Award in Molten Salt and Ionic Liquid Chemistry from the Physical & Analytical Electrochemistry Division of the Electrochemical Society S. Tsai, "The Index of Dry-Jet Wet Spinning for Polyacrylonitrile Precursor Fibers," Journal of Applied Polymer Science 132 (2015): 41265. Yu, "Structure and Properties of Partially Cyclized Polyacrylonitrile-Based Carbon Fiber-Precursor Fiber Prepared by Melt-Spun with Ionic Liquid as the Medium of Processing," Polym. San Marchi (Sandia National Laboratories), Amit Naskar (Oak Ridge National Laboratory), Hee Seok Roh (Argonne National Laboratory) Pacific Northwest National Laboratory P. Evaluate polymeric and metallic liner material options, investigating the combined effects of hydrogen and low temperature. Establish protocols for conducting cryogenic, ambient, and elevated temperature mechanical testing to evaluate potential for micro-crack formation, combining thermal cycling with cyclic mechanical fatigue. Conduct finite element simulations and analytical models of filament-wound composite tank cylinders, using material parameters generated by the project, to estimate tank pressure retaining and burst performance. Formulate damage tolerance models and conduct studies to define acceptability envelopes for defects in liners and composites. Develop models and experimental test methodologies that predict material and pressure vessel performance in hydrogen infrastructure environments. Use knowledge gained to inform material development and selection for improved resistance to hydrogen-induced degradation, therefore improving reliability and durability, and reduce system weight, volume, and cost. Disseminate material characteristics to the community that will assist in improving materials in hydrogen infrastructure components. New highperformance materials will be needed that are inexpensive and lightweight yet strong and resistant to degradation and failure under thermal and pressure cycling in the presence of hydrogen. These materials must resist micro-cracking, avoid loss of volatile constituents, and maintain stiffness and ductility under extreme environmental conditions. While some specialty materials have been proposed, manufacturers typically test the performance of storage vessels using sub-scale and full-scale prototypes, and these tests are expensive and require large amounts of material. The ability to screen materials, composite laminates, and liner materials for use in hydrogen service conditions without such testing would greatly facilitate innovation in alternative materials. The project includes tests of both resin and carbon fiber composite and aluminum and stainless welded liner systems over this temperature range. Parameters derived from experimental testing will be used in numerical models to predict the relative change in full tank burst properties at different temperatures. These simulations will enable development and deployment of existing and new polymer material systems in high pressure sub-ambient and cryogenic hydrogen pressure vessels. Further inspection of the fracture surfaces revealed that all fractures initiated at the corners of the square cross-section, resulting in an artificially low tensile strength measurement that was deemed not representative of the mechanical properties. To mitigate this issue, a new specimen geometry (Figure 1) with circular cross-section and smaller dimensions overall was designed to reduce the total number of defects present in each specimen. A new molding system and curing strategy was adopted to cast specimens with minimal defects and warping during the cure cycle.

Order genuine desyrel on-line. The Shocking Truth About Separation Anxiety - Don Sullivan The DogFather.

Reversible fuel cells are capable of operating in both power production (fuel cell) and energy storage (electrolysis) modes anxiety symptoms over 100 purchase genuine desyrel. A key challenge to reversible fuel cells is maintaining electrode function and performance during repeated cycles between fuel cell and electrolysis modes anxiety symptoms uti discount desyrel 100mg amex. Develop hardware that allows operation of a membrane electrode assembly in both fuel cell and electrolyzer modes without having to remove the membrane electrode assembly anxiety 60mg cymbalta 90 mg prozac buy discount desyrel 100mg online. This result anxiety symptoms blurred vision generic desyrel 100mg with amex, however, has not been demonstrated in an electrolysis membrane electrode assembly devoid of free ions. Membrane characteristics such as composition, fiber diameter, and the incorporation of catalysts/particulates at the interface/junction will be tested first in either individual fuel cell or electrolyzer devices. It is likely that the final reversible fuel cell membrane electrode assembly will require catalyst and electrode architectures that differ significantly from those used in single-application devices. The advantage of having a 3-D interface can also be seen in Figure 1 where the greater area of catalyzed interfacial layer leads to lower cell voltages at the same current densities. The anionic ionomer has to be electrospun in the iodide form and must be exchanged to the hydroxide form for operation. Once in the hydroxide form, it is too mechanically unstable to be manipulated or electrospun. One way around this is to ion exchange a 2-D film of the anion exchange ionomer and make a 2-D interface by applying catalyst to the interface, which allows testing in fuel cell mode. Graphene oxide is used for electrolysis mode testing because it is a better water dissociation catalyst. Carbon is used for fuel cell mode testing because it is better as a water recombination catalyst. The 2-D membrane tested in fuel cell mode has the same nominal thicknesses as above but has carbon catalyst at the interface. The anion exchange membrane resistance was calculated to be 69 m cm2 (2-D) and 55 m cm2 (3-D), while the cation exchange membrane resistance was 36 m cm2 (2-D) and 34 m cm2 (3-D). In electrolysis mode, the resistance of the interfacial junction with graphene oxide was found directly from impedance measurements. In fuel cell mode, the resistance of the interfacial junction with carbon was calculated by subtracting the resistance attributed to Nafion, the anion exchange membrane, and other electronic losses from the highfrequency resistance measured in fuel cell testing. The junction resistances found at various current densities appear in Figure 3 and show that we have not achieved our target interfacial resistance of 200 m cm2. Hydrogen Production-Catalyst, catalyst support, and membrane electrode assembly: o o F: Capital cost G: System efficiency and electricity cost. Compared to commercial Ir black, IrPt 90-10@TiO2 has 46 mV higher overpotential at 100 mA/mg-Ir. If the electrolyzer and fuel cell are separate devices, the system is termed a discrete reversible or regenerative fuel cell; the combination of the two processes in one device is termed a unitized reversible or regenerative fuel cell. The deposition procedure was altered such that all the Ir was deposited first followed by deposition of Pt. The rationale behind this was to maximize the electrochemically-active surface area of Pt. It has also been shown, by 3M, that an Ir underlayer on their nanostructured thin film-supported catalysts improves the durability of a Pt overlayer. Due to these transport-related limitations, the overpotentials were compared at 5 mA/cm2-geo rather than the milestone target of 10 mA/cm2-geo. The catalyst composition using commercial Pt and Ir black had previously been down-selected to 10/90 at % ratio, respectively. The test consisted of a fuel cell break-in followed by fuel cell and electrolyzer performance testing. The fuel cell test first was found to result in better fuel cell performance then when the cell was operated as an electrolyzer first. Periodically the test was stopped in order to test the electrolyzer and fuel cell performance. Round-trip efficiency is calculated by the following formulas, at 1 A/cm2 in respective mode of operation: the degradation is limited to fuel cell mode; after an initial improvement in performance, the performance degrades. The gap is due to this test being performed over the course of 24 h; it was timed so that the beginning and end point performance tests could be obtained during work hours.

All four component precursor green films were successfully printed anxiety 8 year old boy discount desyrel online visa, with active areas higher than 100 cm2 and very smooth surface health anxiety symptoms 247 cheap desyrel 100mg on line. These results already met our milestone request (100 cm2 for green component films) anxiety klonopin order discount desyrel on line. Figure 2a shows that the three layers of H2 electrode anxiety symptoms checklist pdf discount desyrel 100 mg mastercard, electrolyte, and O2 electrode were bonded together very well. Figure 2b shows a representative cross-sectional image of electrolyte green film printed on H2 electrode film. The excellent bonding between the electrolyte film and the H2 electrode film was achieved for 3-D printed green half cells. The green half cells having a much larger area than the width of the laser beam through the cylindrical lens always resulted in the sintered stripes separated from the region without sintering. Therefore, we removed the edge effect by printing half cells in a narrow width in the dog bone shape. Figure 3 provides a summary photo of 13 half cells, which has a total active area around 120 cm2. The preparation of this amount of half cells allows us to further integrate them into large-area cells or stacks, which is significant progress on this project. The I-V and I-P curves of these single cells at different temperatures are shown in Figure 4c. As the temperature increased from 550 to 650, the total resistance of the single cell (Rt) decreased from 1. Decrease the electrolyte thickness and optimize the microstructure and composition to achieve ohmic resistance lower than 0. To speed up the technology to market, an industrial partner who is interested in scaling up this technology will be located. Brinkman, "A High-Performance Reversible Protonic Ceramic Electrochemical Cell based on a Novel Sm-Doped BaCe0. Demonstrated the pilot-scale fabrication processes of areal production rates of 4. Demonstrated that the project anode electrode technology is capable of yielding high performance with ultra-low Ir loadings of 0. Initiated development of roll-to-roll quality control/inspection methods for assessment of spatial variations of membrane thickness and catalyst loadings, with initial feasibility demonstrated for some component configurations. In combination, the higher manufacturing rates, ultra-low catalyst loadings, and high performance may address the three key cost barriers above and may enable significant decreases in both electrolyzer system capital costs and hydrogen production costs. Initial development work will occur at laboratory and pilot scale, with the objective of identifying scalable process methods that enable reliable production of components at approximately 3x lineal rates, relative to the baseline process, at 0. The primary input raw materials for the overall process are commercially available 3M ionomer powder, Ir and Pt sputter targets, and perylene red 149 powder. The work consisted of several process experiments that occurred at laboratory, pilot, and production scale. Due to limited solubility of the ionomer in typical alcohol/water solvent systems, the as-cast wet membrane films are relatively thick and contain significant amounts of solvent, which must be removed during the drying step.